Recent supply chain network optimization is a strategic process that improves supply chain performance by leveraging AI/ML-based algorithmic modeling. Its main aim is to maximize efficiency and reduce costs involved in planning the end-to-end movement of goods. Essentially, it’s about making the supply chain run smoother, more efficiently, and better overall.

~How does supply chain optimization work?~

Supply chain optimization involves several key steps to enhance efficiency and reduce costs in the movement of goods. Here’s a high-level overview:

Data Collection and Analysis:

- Gather data on suppliers, transportation, inventory, demand, and costs.

- Analyze historical data to identify patterns and trends

Modeling and Simulation:

- Create mathematical models (e.g., linear programming, network flow) to represent the supply chain.

- Simulate scenarios to evaluate different strategies.

Network Design:

- Determine the optimal number and location of facilities (e.g., warehouses, distribution centers).

- Consider factors like transportation costs, lead times, and service levels.

Inventory Management:

- Optimize inventory levels to balance cost and service.

- Use techniques like safety stock, reorder points, and economic order quantity (EOQ).

Transportation Optimization:

- Optimize routes, modes, and carriers.

- Minimize transportation costs while meeting delivery requirements.

Demand Forecasting:

- Accurate forecasts help plan production and inventory.

- Leverage statistical methods and machine learning for better predictions.

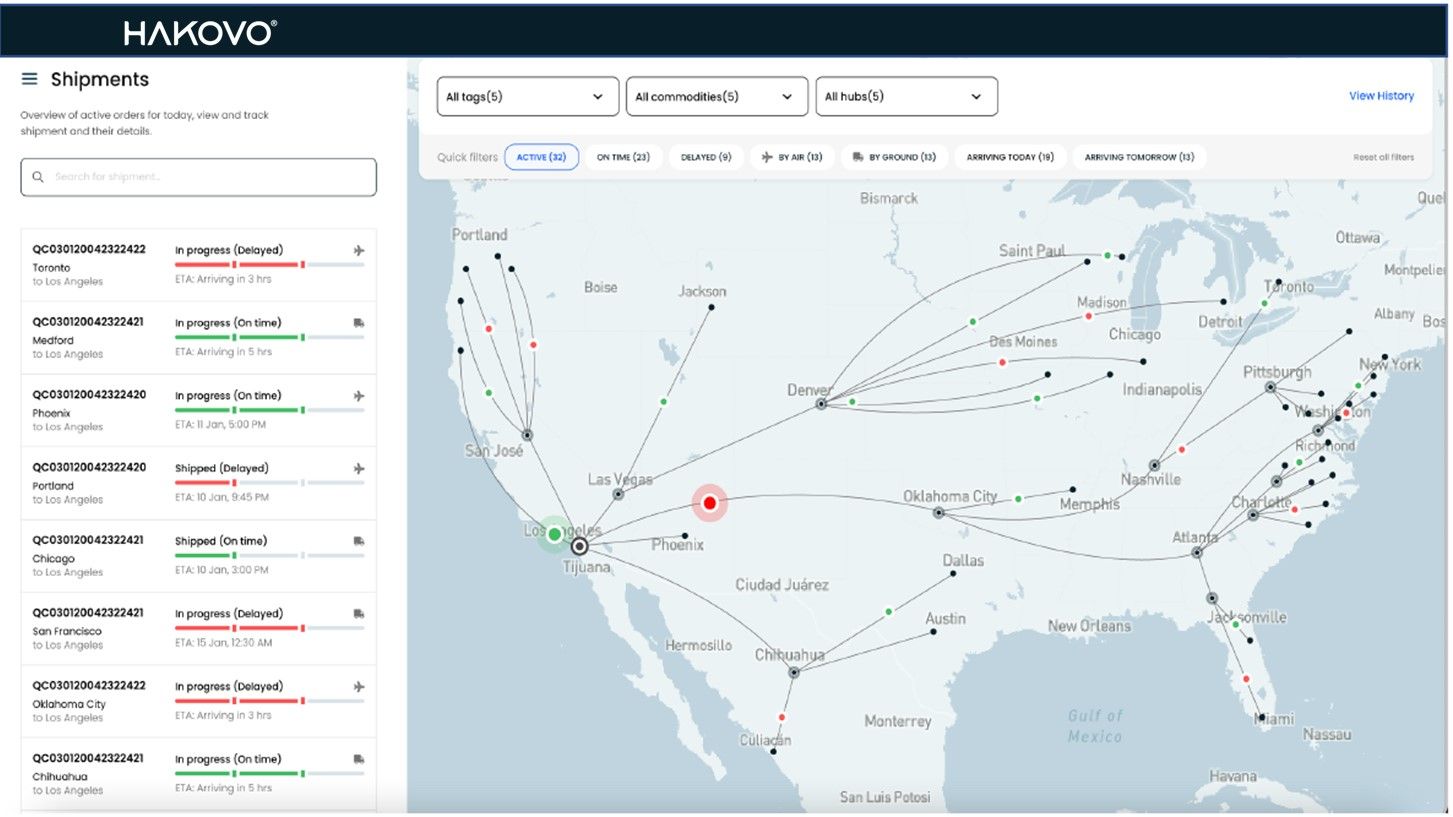

Collaboration and Visibility:

- Improve communication across supply chain partners.

- Real-time visibility into inventory, orders, and shipments.

Continuous Improvement:

- Monitor performance metrics (e.g., fill rate, on-time delivery).

- Adjust strategies based on changing market conditions.

Supply chain optimization is an ongoing process, adapting to dynamic business environments and evolving customer demands.